The Bay Area startup behind Shark Tank’s seaweed-based bacon

From the article in the San Jose Mercury News by John Metcalfe.

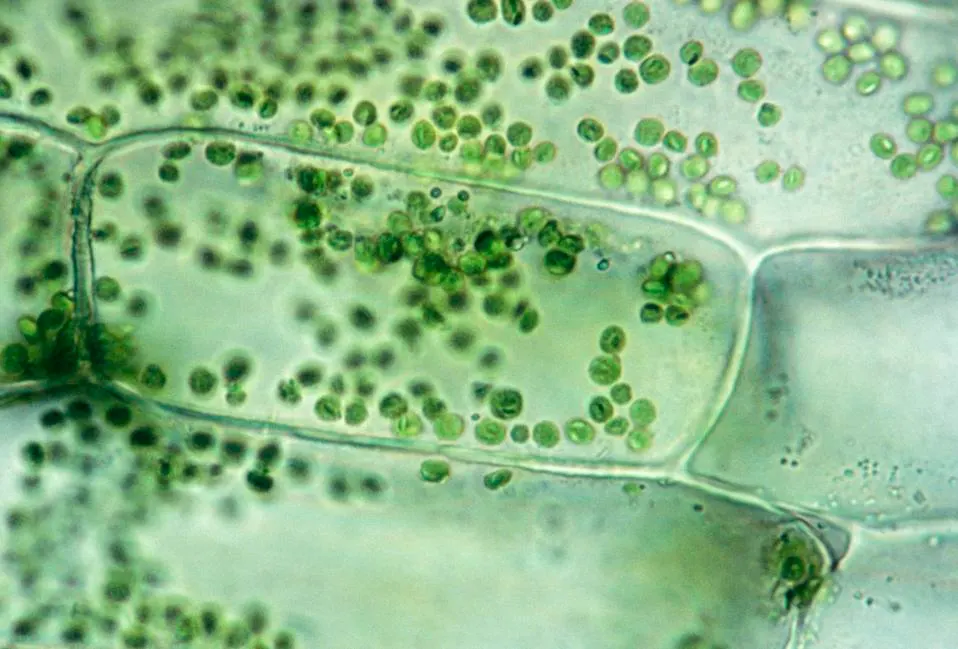

Umaro Foods is betting that soon, the world’s going to be eating a whole lot more seaweed protein.

Seaweed might not be the first thing you think of sidling up on a plate with fried eggs and hash browns. But it’s high in protein, one of the fastest growing plants on earth, and requires no land, fresh water, or fertilizer. As the world’s food-supply chain gets ever more stressed – a result of climate change, population growth, unpopular tarriffs and the like, it’s being seen as a viable future food, in the vein of cell-cultured meat and cricket flour.

Umaro still makes bacon, but its bigger business is refining seaweeds like kelp via a proprietary process into proteins and high-value ingredients. Soon, it might also move into biodegradable packaging. Zotter recently took a few minutes to chat about what’s on the horizon.

Q: What’s the best way to describe what Umaro does?

A: We’re not a plant-based meat company. We’re a seaweed-refining company. We figured out a way to unlock the individual molecules in seaweed for higher-value applications. Our process actually produces two products: One is protein and the other is alginate.

Q: What’s the protein used for?

A: What is really popular right now, and I just don’t see any signs of it abating, is protein enrichment. You see protein-enriched pastas and crackers, so I’m excited to work with partners who want to use this ingredient to make things like dumplings and noodles. A lot of people are trying to get more protein into their diets, sort of a result of the GLP-1 and keto diets. They’re like, “If you’re going to eat pasta, at least get some more protein in there and make it nutritionally balanced.”

And the global market of protein is about $25 billion for protein ingredients, isolates and concentrates.

Q: What’s this alginate stuff?

A: It’s a specialty chemical worth a lot of money – like, $20,000 a ton. Alginate is usually added as an ingredient into things you wouldn’t notice. It’s also used for the casings of sausages, so it makes a good, clear film. I don’t know if we’ll actually get this grant or if it will be canceled (by the current administration), but we recently won an award from the Department of Energy to use our alginate to make a biodegradable plastic film. Our partner on that award is (the San Leandro startup) Sway.